Pulse Laser Cleaning Machine For Mold Cleaning

Laser cleaning is a technology that uses a focused laser to act on the surface of a material to rapidly vaporize or peel off the contaminants on the surface, so as to clean the surface of the material.

Description

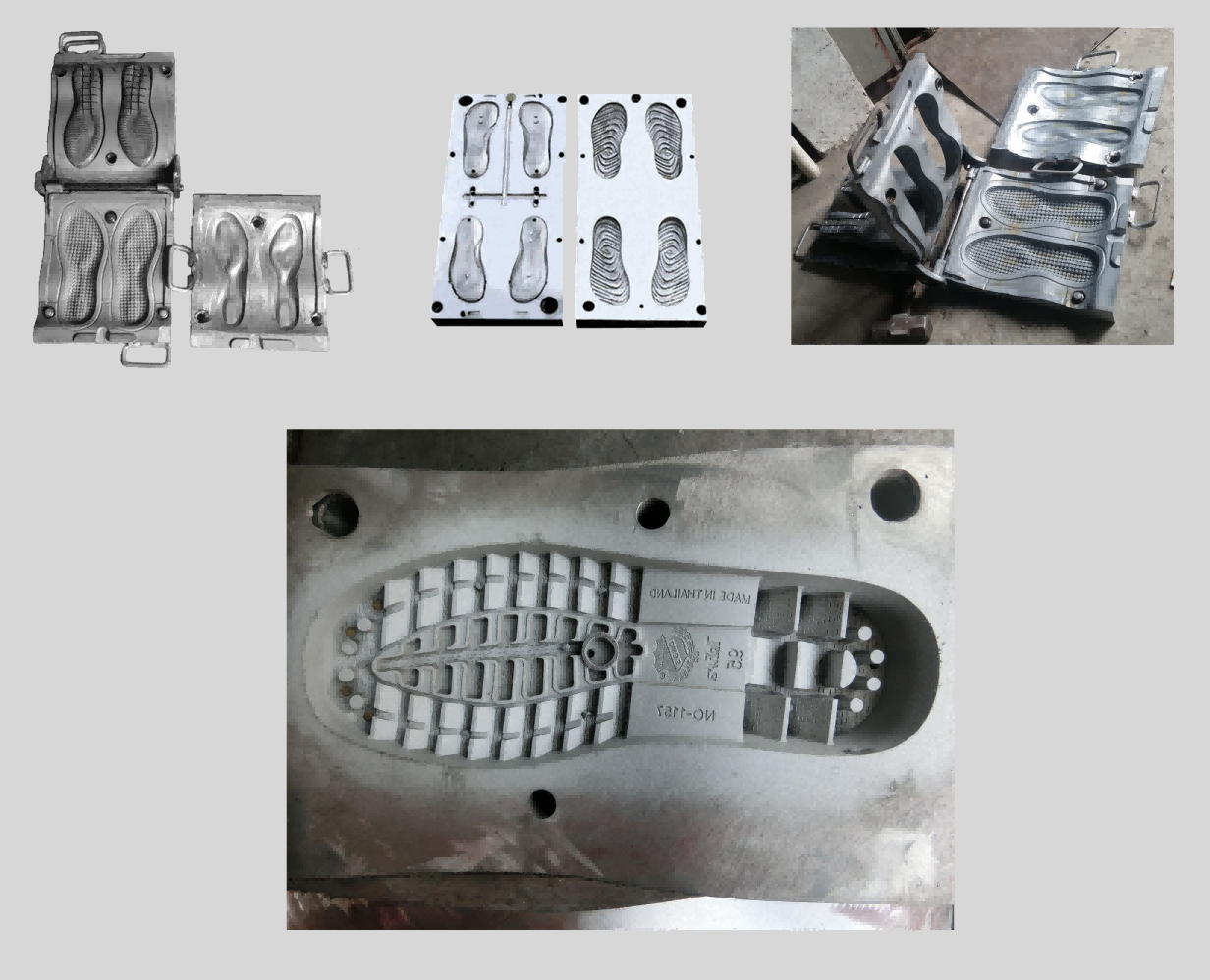

Mold cleaning in the manufacturing industry is a cumbersome task that involves the use of harsh chemicals and abrasive tools. However, with the advent of laser cleaning machines, the process is becoming more efficient, environmentally friendly, and cost-effective. A laser cleaning machine uses high-intensity laser beams to remove dirt, rust, paint, and other unwanted materials from the surface of molds. This technology has numerous benefits and has proved to be the ultimate solution for mold cleaning.

Products application

| The mold laser cleaning machine can clean various types of molds, including plastic molds, metal molds, glass molds, etc. The mold pulse laser cleaning machine can effectively remove the oil, residue and dirt on the surface of the mold, and improve the cleanliness and reliability of the mold. Laser cleaning technology has high precision and effect in the field of mold cleaning. It can clean molds with complex shapes, improve production efficiency and prolong the service life of molds. |

Products parameter

| 300w Pulsed Laser Cleaning Machine | |||

|

Model |

LG-FL-300A |

Laser wavelength |

1064nm |

|

Laser output power |

>300W |

Laser configuration |

Raycus (optional) |

|

Galvo scanning speed |

>20000mm/s |

Power adjustment range |

10-300W |

|

Repetition frequency range |

1-4000KHZ |

Pulse width range |

10-500ns |

|

Output fiber diameter |

3-8m (standard 5) |

||

|

Spot type |

Gaussian light |

Input power |

110-220VAC 50/60HZ |

|

Single pulse capability |

1.8-10mJ |

Output type |

QCS |

|

Spot diameter |

2-10mm |

Spot shape |

Cycle |

|

Beam quality |

M²<1.6 |

Pulse width adjustable number |

8-20 |

|

Operating temperature |

10-40℃ |

Cooling method |

Water cooling |

|

Machine power consumption |

<1800W |

Total Weight |

<120kg |

Products Feature

High Efficiency

One of the primary advantages of laser cleaning machines is their high efficiency. These machines use powerful laser beams to remove contaminants from the surface of molds quickly, leaving them free from any foreign materials. The process is non-contact, and there is no need for any cleaning agents or abrasive tools. As a result, the cleaning process is much faster than traditional methods, which improves productivity and reduces downtime.

High Cleanliness

The laser cleaning process is highly precise, ensuring that the surface of the mold is left with zero residues. This is because the laser is programmed to only target the contaminants, while the underlying substrate remains intact. Unlike traditional cleaning methods, which may leave behind scratches or residues on the mold's surface, the laser cleaning process is gentle and does not damage the substrate. This guarantees a high level of cleanliness, ensuring that the mold is usable for an extended period.

Non-Destructive

Another benefit of laser cleaning machines is that they are non-destructive. The laser beam does not strip, wear, or erode the surface of the mold, making it an ideal option for delicate materials. It also eliminates the need for toxic chemicals, which are harmful to the environment and can cause severe health problems to workers handling them.

Precision Cleaning

Precision cleaning is the hallmark of laser cleaning machines. The cleaning head is flexible and can easily adjust to the contours of the mold, ensuring that every nook and cranny is thoroughly cleaned. Additionally, the machine can be programmed to clean specific areas in a mold, making it ideal for targeted cleaning of complex geometries. This precision ensures that molds are cleaned to the highest standards, which reduces the risk of defects in the final product.

Ease of Operation

Laser cleaning machines are easy to operate and require minimal training. The cleaning process is automated and can be controlled by a single operator, reducing labor costs. Additionally, the machine is fitted with safety features that prevent accidental exposure to the laser beam, making it safer to use.

Laser Cleaning Mathod Comparision

Mold Laser cleaning machine selection

Choose the right laser cleaning machine for your needs.

If you have any needs, you can consult customer service and recommend suitable models for you.

We can also make personalized non-standard customization according to your processing needs.

Hot Tags: pulse laser cleaning machine for mold cleaning, China pulse laser cleaning machine for mold cleaning manufacturers, suppliers, factory, laser rust removal machine, 100w metal surface rust removal laser cleanner, large format laser cleaning machine, iron rust cleaning machine, portable fiber laser cleaning machine, metal derusting laser cleaning machine

You Might Also Like