Want Your Own Laser Rust Removal Machine Solution?

Look no further! what you need is Legent Laser laser rust removal machine solution.

In busy industrial production, the problem of equipment rust has been plaguing many companies. Traditional rust removal methods are not only inefficient, but can also cause harm to operators. The Legent Laser laser rust removal machine solves this problem for you.

Using the most advanced laser technology, the Legent Laser laser rust remover can remove rust in a short time without causing any damage to the equipment itself. Not only that, this rust remover also has the characteristics of high precision, high efficiency, safety and reliability, etc., which can bring many advantages to your company.

If you are looking for an efficient, safe, and reliable laser rust removal machine solution, Legent Laser's Ultimate Guide to Laser Rust Removal Machine is here to help.

Get Your Laser Cleaning Machine Solution Here!

Large Power Laser Cleaning Machine For Agricultural Machinery IndustryInquiry Now

1500w Laser Cleaning Machine For Agricultural Machinery IndustryInquiry Now

Pulse Laser Cleaning Machine For Agricultural Machinery IndustryInquiry Now

Flat-top Laser Cleaning Machine For Agricultural Machinery IndustryInquiry Now

What Is Rust And Why Do Metals Rust?

Rust is a chemical phenomenon that refers to the oxidation process of metal in the air. During this process, atoms on the metal surface react with oxygen to form a new compound, an oxide. This process is usually accompanied by some obvious phenomena, such as corrosion on the metal surface, color changes, increased surface roughness, etc.

There are two main reasons why metal rusts. First of all, metals are reactive elements and they easily react with other elements in nature. Secondly, the oxidation process on the metal surface is usually caused by moisture and oxygen in the environment. When metal surfaces come into contact with these substances, they form an electrochemical reaction that accelerates the oxidation process of the metal.

Different kinds of metals have different resistance to corrosion, depending on their position in the periodic table and their chemical properties. For example, precious metals such as gold and platinum are difficult to rust due to their high reactivity. In contrast, more reactive metals such as iron and aluminum are prone to rust. To prevent metal from rusting, you can use anti-rust coatings or take other anti-rust measures, such as electroplating, painting, etc.

What Types Of Metals Rust?

Different types of metals have different chemical properties. Some metals are easily oxidized, while others are relatively stable. Among many metals, iron is one of the most susceptible to rust. When iron comes into contact with oxygen and water vapor in the air, a layer of oxide is formed, which is commonly known as rust. In addition to iron, some other metals can rust under certain conditions, such as copper and aluminum. But the rusting process of these metals is different from that of iron.

Copper develops a patina in humid environments as it reacts with oxygen, water and carbon dioxide to form basic copper carbonate. This reaction usually occurs when copper is exposed to outdoor conditions. However, copper is relatively stable and less likely to rust if left in a completely dry environment.

Aluminum is a very reactive metal, but when it reacts with oxygen in the air, it produces a thin film of aluminum oxide that protects the aluminum from further oxidation. Therefore, aluminum is less likely to rust under normal conditions.

In addition to these common metals, precious metals such as gold, platinum and silver generally do not rust. This is because the chemical properties of these metals are very stable and do not easily react with surrounding substances. However, these metals are very rare in the earth's crust, so they are not common metallic materials in our daily lives.

In short, among common metal materials, iron is one of the most prone to rust. But some other metals can also undergo oxidation reactions under certain conditions. Understanding the chemical properties of different metals can help us better prevent and control metal rust.

What Is A Laser Rust Removal Machine?

Laser rust removal machine is a device that uses high-energy laser beams to irradiate the rusted surface to quickly melt, vaporize or reach ignition conditions to achieve rust removal. Compared with traditional mechanical rust removal and chemical rust removal methods, laser rust removal has higher efficiency, lower cost and better environmental performance.

Laser rust removal machine mainly consists of laser, cooling system, optical path system and control system. Among them, the laser, as the core component, can generate high-energy laser beams, and its power and wavelength determine the rust removal effect and speed. The cooling system is used to reduce the temperature of the laser to avoid equipment damage caused by overheating. The optical system is responsible for transmitting the laser beam to the corroded surface, and at the same time, the size and shape of the light spot can be adjusted to adapt to corroded areas of different shapes and sizes. The control system controls the entire equipment, including the switching of the laser, the operation of the cooling system, and the adjustment of the optical path system.

Laser rust removal machine is suitable for rust removal on various metal surfaces, such as steel, copper, aluminum, etc. Due to its high efficiency and environmental protection, laser rust removal machines are widely used in many fields, such as shipbuilding, petrochemical industry, electric power, automobile manufacturing, etc. When using a laser rust removal machine, professional technicians need to operate it and pay attention to safety precautions, such as wearing protective glasses and avoiding direct exposure of the laser beam to the human body.

In short, the laser rust removal machine is an efficient, environmentally friendly rust removal equipment with wide application prospects.

How Does A Laser Rust Removal Machine Work?

Laser rust removal machine is an efficient and environmentally friendly rust removal equipment. Its working principle is to use high-energy laser beam to irradiate the rust surface, causing the rust to quickly melt, vaporize or reach the ignition point. At the same time, the high-pressure shock wave generated can melt the melted rust. The rust material is quickly exploded into fine particles and discharged with the flue gas, thereby removing the rust.

Laser rust removal machine mainly consists of laser, optical path system, control system, dust removal system, etc. Among them, the laser is the core part, which can emit a high-energy laser beam; the optical system can guide the laser beam to the rusted surface; the control system can control the switching and operation of the laser beam; and the dust removal system can remove smoke and particulate matter.

When operating a laser rust removal machine, you need to clean and treat the rusted surface first, and then adjust the power and beam quality of the laser so that it can illuminate the rusted surface. When the laser beam is irradiated on the rusted surface, the rust will quickly melt, vaporize or reach the ignition point, and the high-pressure shock wave generated will quickly explode the melted rust material into fine particles and be discharged with the smoke. During the operation, you need to pay attention to protect your eyes and skin to avoid direct exposure to the laser beam.

Compared with traditional manual rust removal methods and chemical rust removal methods, laser rust removal machines have higher rust removal efficiency and a more environmentally friendly rust removal method. At the same time, the laser rust removal machine also has a wide range of applications and can be used for rust removal operations on various metal surfaces.

What Are The Characteristics Of Handheld Laser Rust Removal Machine?

The handheld laser rust removal machine is a modern cleaning equipment that uses high-energy laser beams to irradiate objects with rough surfaces, causing dirt and rust on the surface to instantly heat, expand and vaporize, thereby quickly falling off the surface of the object. This rust removal method has the advantages of high efficiency, environmental protection, energy saving, etc., and has been widely used in cleaning and rust removal work in various industrial and commercial places.

The characteristics of the handheld laser rust removal machine can be summarized in the following aspects:

1. Efficient rust removal: The laser rust removal machine can quickly remove dirt and rust on the surface of the object without causing any damage to the surface of the object, improving the efficiency of rust removal.

2. Environmental protection and energy saving: The laser rust removal machine uses electric energy as energy, does not produce noise and pollutants, and is environmentally friendly. At the same time, it consumes less energy and has high energy utilization efficiency.

3. Easy to operate: The handheld laser rust removal machine is lightweight and easy to operate, and can be easily moved to different places for rust removal work.

4. Wide range of application: The handheld laser rust removal machine is suitable for removing rust from the surfaces of various materials, such as steel, stainless steel, aluminum alloy, etc. At the same time, it is also suitable for objects of various shapes, such as planes, curved surfaces, pipes, etc.

5. Safe and reliable: The laser rust removal machine uses a high-energy laser beam, but the operator will not be exposed to the laser beam during use, which is safe and reliable.

6. Customizable: The handheld laser rust removal machine can be customized according to different needs to meet the needs of different customers.

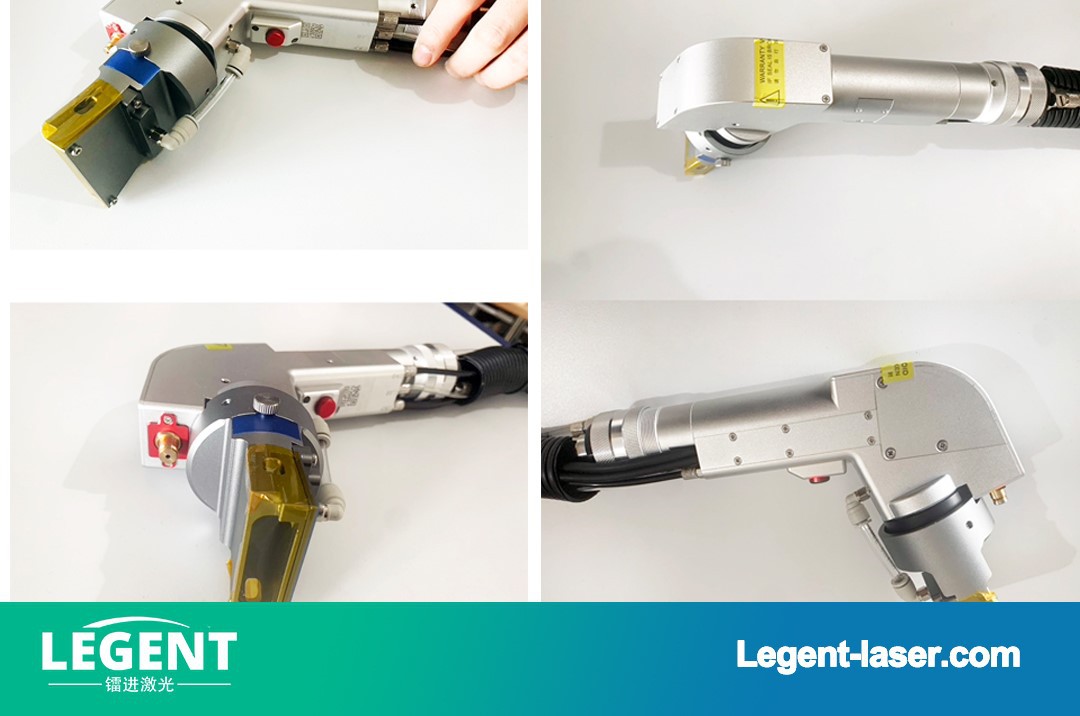

What Is A Laser Rust Removal Gun?

The laser rust removal gun includes a gun shell, a galvanometer scanning component and an aperture component. The laser generated by the laser generator is scanned by the galvanometer to form a linear spot, which is emitted from the square light hole of the iris towards the object to be cleaned. , the whole constitutes the light output channel. The adjusting aperture can slide along the length of the luminous hole on the fixed aperture, thereby changing the luminous length of the luminous hole so that it is consistent with the size of the linear light spot, thereby preventing return light from entering the gun shell during the cleaning process. The laser rust removal gun has a simple structure and is easy to use, and can process any highly reflective profile. Can be adapted to different types of laser generators. At the same time, the contact between the optical components in the laser rust removal gun and the outside world is closed to avoid contamination.

In addition to being used for handheld laser cleaning, laser rust removal guns can also be installed on moving mechanical equipment (such as robots, manipulators, CNC machine tools, etc.), and the mechanical equipment automatically completes the preset movement trajectory. Its advantages are high precision, large scale of operations, low technical requirements for operators and low labor intensity.

Features Of Laser Rust Removal Gun

The laser rust removal gun is an efficient and environmentally friendly rust removal tool. Its characteristics are as follows:

Efficiency: The laser rust removal gun can quickly and accurately remove rust and dirt on the surface of various materials, improving work efficiency.

Applicability: The laser rust removal gun is suitable for surfaces of various materials and shapes, such as steel, aluminum alloy, plastic, etc.

Portability: The laser rust removal gun is small in size and light in weight, making it easy to carry and operate. It weighs less than 1KG and is more conducive to long-term handheld operation.

Durability: The laser rust removal gun is made of high-quality materials for long service life and easy maintenance.

Safety: The laser rust removal gun will not generate high temperatures during use, avoiding safety hazards during operation.

Adjustability: The laser rust removal gun has adjustable beam size and power, which can be adjusted according to different needs.

Easy to operate: The laser rust removal gun is simple to operate, ergonomically designed and suitable for operators of all skill levels.

Simple maintenance: The laser rust removal gun does not need to frequently replace parts during use, and the maintenance cost is low.

Reliability: The laser rust removal gun adopts advanced laser technology, has stable and reliable performance, and can ensure the effect of long-term use.

Dust-proof sealing design: independent modular design of optical path, sealed and dust-proof.

Detachable vacuum nozzle: independent detachable vacuum nozzle design, with flexible and adjustable height and angle.

Portable Handheld Laser Rust Removal Machine Application

Laser rust removal machines are widely used in the mold industry, hardware industry, automobile industry, medical industry, electronics industry, home kitchenware and bathroom and other fields.

1. Remove rust from metal surfaces.

2. Surface paint removal and spray painting treatment.

3. Clean the surface without dirt, stains, or grime.

4. Surface coating and coating removal.

5. Clean up oil stains and pollutants.

6. Welding surface and spraying surface pretreatment.

7. Clean up rubber, plastic and metal mold residues.

Portable Handheld Rust Removal Machine Packaging And Shipping

The packaging of the machine is very particular. In order to ensure the safe transportation of the machine, we have adopted double protection measures. First, we wrap the machine with a moisture-proof film to prevent moisture from causing damage to the machine. Secondly, we also wrapped a layer of foam outside the moisture-proof membrane to further protect the machine from shock and vibration. In addition, we also choose high-quality wooden boxes as outer packaging to ensure that the machine can be effectively protected during transportation.

In order to facilitate customers to clear customs without fumigation, we specially selected wooden boxes that do not require fumigation. This not only saves the customer time and effort, but also avoids additional costs caused by fumigation.

In order to ensure the efficiency and convenience of express delivery, we have chosen professional express companies as partners. They provide door-to-door service, just select the express method when purchasing, and the machine can be easily delivered to the destination. Moreover, their service is very efficient and the machine can be delivered safely in the shortest time, so that customers do not have to wait for a long time.

Whether in packaging or express delivery services, we pay great attention to details and service quality to allow customers to enjoy a better shopping experience.

How Much Does A Laser Rust Removal Machine Cost?

At Legent-Laser, prices start at $7,000 for a 1000W portable laser rust removal machine. The price range for 1500W handheld laser rust removal machine starts from $8800. The minimum cost of a 2000W high-power laser rust removal machine is $11,800. 3000W laser rust removal guns start at $13,800. Of course, automatic laser rust removal machines with CNC controllers or robots will be more expensive.

Laser equipment, its price mainly depends on different configurations. Even if the configurations are similar, the costs vary from manufacturer to manufacturer.

For example, if you use a more powerful laser generator, the price will definitely be higher.

For example, the brand, model, power, etc. of laser generators used by different manufacturers will also affect the price.

In addition, the price of laser rust removal machine is also related to its functions, characteristics, uses and other factors.

In addition, some laser rust removal machines use advanced cooling systems, protective devices, etc. These additional functions will also increase the cost of the product.

In addition, the price of laser rust removal machine is also affected by other factors. The cost not only involves configuration, but also factors such as freight, brand, and after-sales service.

In short, the price of laser rust removal machine is a comprehensive issue that needs to consider many factors. When purchasing, you need to choose based on your actual needs and budget.