Molds play a vital role in modern industry and are widely used to manufacture various products. However, mold maintenance and upkeep is a complex and time-consuming process that needs to be performed regularly to keep it in good working order. The timeliness and effectiveness of mold maintenance directly affect the service life of the mold and the quality of the product. Therefore, seeking more efficient and time-saving mold maintenance methods has always been an important issue in the industrial field.

With the continuous development of technology, laser mold cleaning machines have emerged, bringing revolutionary changes to mold maintenance. Laser mold cleaning machines have quickly occupied an important position in the field of mold maintenance with their non-contact, efficient and precise cleaning characteristics. This article aims to introduce in detail how laser mold cleaning machines change traditional mold maintenance methods and improve the efficiency and effectiveness of mold maintenance.

Products Selection

1. Importance Of Mold Maintenance

Mold maintenance is crucial to ensure the normal operation of the mold and improve product quality. During the long-term use of the mold, due to wear, corrosion, aging and other reasons, the surface of the mold will be damaged or internal blockage will occur, affecting the molding and quality of the product. If the mold cannot be maintained and maintained in time, its service life may be shortened or even cause a safety accident. Therefore, mold maintenance is of great significance to ensure production safety, improve production efficiency, and reduce production costs.

The laser mold cleaning machine is a new type of mold maintenance equipment that uses high-energy laser beams to irradiate the surface of the mold to quickly remove dirt, rust, oxides, etc. without causing any damage to the mold. Compared with traditional cleaning methods, laser mold cleaning machines have the advantages of easy operation, good cleaning effect, and saving time and effort. Its emergence has completely changed the traditional manual cleaning method, greatly improved the cleaning efficiency and effect of the mold, and brought revolutionary changes to the maintenance of the mold.

This article will introduce in detail the working principle, advantages and application of laser mold cleaning machines in mold maintenance. We will discuss how to use laser mold cleaning machines for efficient and accurate mold cleaning, and the changes this new cleaning method brings to traditional mold maintenance. In addition, we will also analyze the role of laser mold cleaning machines in improving production efficiency, reducing production costs, and ensuring production safety.

2. Working Principle And Advantages Of Laser Mold Cleaning Machine

1. Working principle:

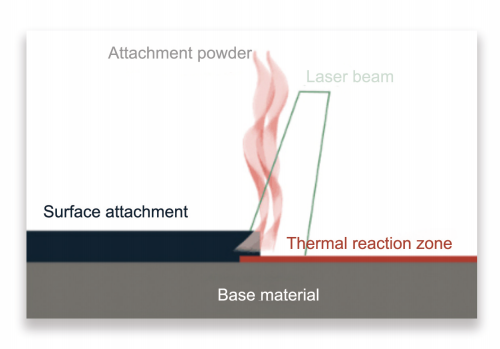

Laser mold cleaning machines use high-energy laser beams to irradiate the surface of the mold to quickly vaporize or expand dirt, grease, oxides, etc. on the surface, thereby separating them from the surface of the mold. At the same time, the high energy density of the laser beam can instantly melt and evaporate some stains on the mold surface that are difficult to clean, and are finally sucked away by the vacuum pump to achieve cleaning purposes.

2. Advantages:

a. Efficiency: The laser mold cleaning machine can complete the cleaning task in a short time, greatly improving work efficiency. Traditional cleaning methods, such as chemical soaking, mechanical polishing, etc., require a lot of time and manpower.

b. Environmental protection: Laser cleaning machines reduce the use of chemical substances, such as chemical solvents, abrasives, etc., reducing environmental pollution. At the same time, waste gas, waste water and other waste after laser cleaning are also effectively processed without causing pollution to the environment.

c. Reliability: Laser cleaning can completely remove stains and oxides on the surface of the mold, improving the quality and service life of the mold. Traditional cleaning methods are often difficult to completely remove the fine parts of the mold surface, resulting in a shorter service life of the mold.

d. Flexibility: Laser cleaning machines are suitable for various mold materials and shapes, such as molds made of metal, plastic, rubber and other materials, as well as molds with complex geometric shapes and minute details. This is difficult to achieve with traditional cleaning methods.

e. Safety: The laser cleaning machine is simple to operate, reducing labor costs and safety risks. Traditional cleaning methods often require manual operation, which can easily cause personal injury and mold damage.

3. Application Of Laser Mold Cleaning Machine In Mold Maintenance

1. Efficiently clean various molds: Whether it is injection molds, die-casting molds or stamping molds, laser mold cleaning machines can quickly and effectively remove dirt, residue and oxides on the surface of the mold, improve the surface finish of the mold, and create better products. Lay the foundation for high-quality products.

2. Improve product quality: The mold after cleaning by the laser mold cleaning machine will be brighter, which can greatly improve the aesthetics of the product. It can also improve the quality of the product and reduce the defective rate.

3. Extend the service life of the mold: The laser mold cleaning machine can effectively remove dirt and oxides on the surface of the mold to avoid damage to the mold due to long-term use, thereby extending the service life of the mold.

4. Reduce production costs: The use of laser mold cleaning machines can reduce the frequency of mold replacement and maintenance costs, improve production efficiency, thereby reducing the cost of the entire production process. At the same time, the cleaned mold can also reduce the failure rate during the production process and further reduce production costs.

4. Case Analysis

5. Conclusion

1. Laser mold cleaning machines have significant advantages and application prospects in mold maintenance

In the field of mold maintenance, laser mold cleaning machines are considered to be equipment with significant advantages. Compared with traditional manual cleaning methods, laser mold cleaning machines can clean molds faster and more efficiently, while avoiding scratches and damage that may be caused by manual cleaning. This cleaning machine has a wide range of applications and is suitable for various types of molds, including injection molds, die-casting molds, stamping molds, etc. In many industries such as automobiles, electronics, and medical care, mold cleaning and maintenance are crucial, so the application prospects of laser mold cleaning machines are very broad.

2. By changing the traditional mold maintenance method, laser mold cleaning machines can bring higher production efficiency and lower production costs to enterprises.

The use of laser mold cleaning machines can completely change the traditional mold maintenance methods. The traditional manual cleaning method is not only inefficient, but also has unsatisfactory cleaning effects and can easily cause damage to the mold. The laser mold cleaning machine can complete high-precision cleaning in a short time, improve production efficiency, and reduce production costs at the same time. Specifically, this kind of cleaning machine can reduce labor costs, reduce energy consumption, reduce mold damage and repair times, thereby saving a lot of costs for enterprises. In addition, due to the improved cleaning effect, the quality of the product will also be improved, further increasing the company's profits. Therefore, the use of laser mold cleaning machines is a win-win method, which not only improves production efficiency but also reduces production costs.